Because the 2024 snow season ended, the Perisher upkeep crew has been arduous at work eradicating the Mount Perisher Triple Backside drive-station, making method for development to start out on the underside station. The crew will now concentrate on works greater up the hill.

The most important win to date has been Doppelmayr developing with an progressive answer to concrete provide points by putting in its personal batch plant in Jindabyne. This, together with the preparatory works accomplished pre-season to make sure a protected entry highway to the highest station, has been invaluable and fast-tracked the venture.

Over winter, Shaun Turner, Basic Supervisor of Mount Perisher 6 development associate Doppelmayr, had the progressive thought to create the corporate’s personal concrete supply to chop down on the dangers related to unsure concrete provide points. “Our crews have been working lengthy hours and into the evening to maintain to schedules set by concrete vegetation,” explains Shaun. “It wasn’t sustainable, and the time we would want concrete was usually outdoors regular enterprise hours, which made it arduous to depend on native vegetation.”

The supply and reliability of concrete provide grew to become one of many highest venture dangers, particularly when the delays meant crews would possibly want to attend round till the concrete arrived if the supply occasions have been pushed again. As an answer, Doppelmayr utilized for a Improvement Utility to supply its personal concrete, which was granted. This October, Doppelmayr has made round 400 cubic metres of concrete, which has been positioned on-site.

“A superb instance of how efficient it’s been was simply this week once we excavated Tower Two. By 11:00 a.m. on Monday, it was excavated. At noon, we had geotechnical approval and by 1:00 p.m. the concrete was in. This course of would usually take a couple of days between every step. It’s making an enormous distinction.”

He defined the method of creating concrete as like baking a cake the place there are many completely different components, strategies and outcomes. “We use sand, aggregates, cements and fly ash, putting all of it collectively within the truck and mixing it as much as the appropriate consistency earlier than taking it to the location, round an hour away,” stated Shaun. “We now have an inner reserving system so a crew might ebook the concrete 2-3 days out, and even as little as 1-2 hours upfront.”

It takes about an hour to create 30 cubic metres of concrete at Doppelmayr’s Jindabyne concrete plant, and one other hour to move it to the Perisher website. A Improvement Approval has been introduced for a Smiggins concrete plant to make it even faster to turnaround concrete for the Mount Perisher 6 venture.

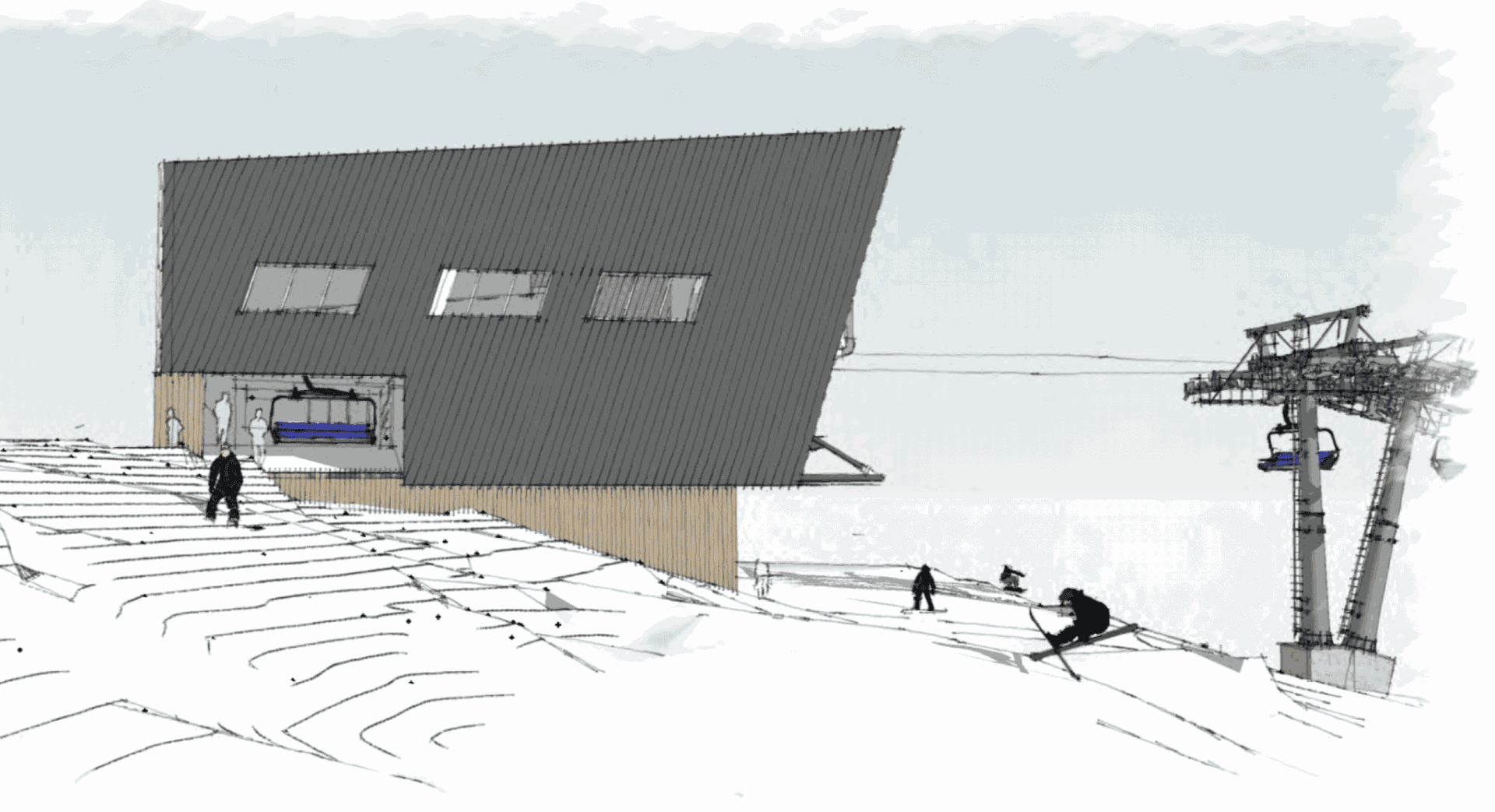

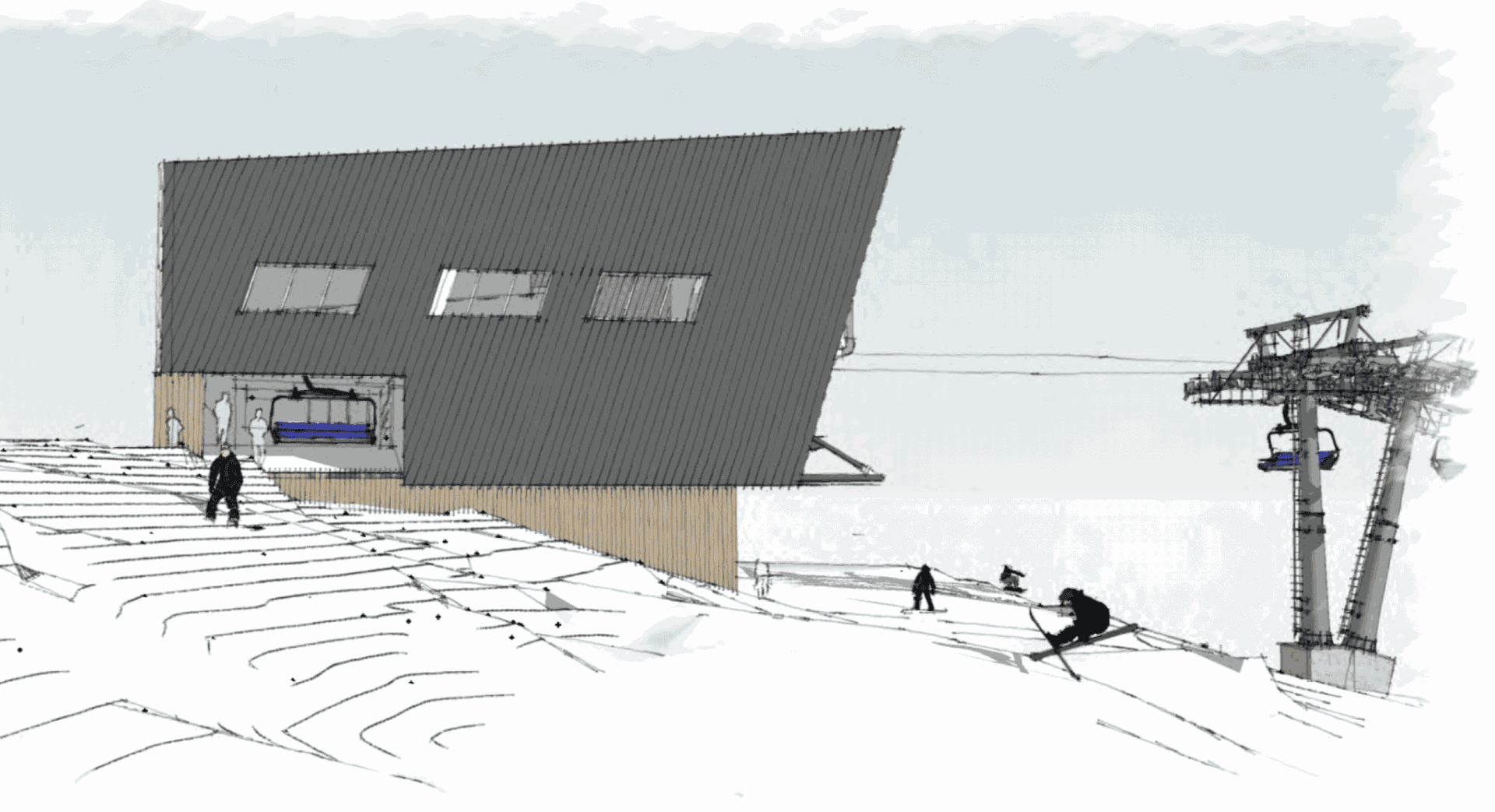

The Mount Perisher 6-Chair is anticipated to be prepared for the 2025 Australian winter season. The brand new Doppelmayr chairlift will function at a pace of 4.5 metres per second, slicing journey time up the mountain from 11 minutes for the Double-Chair and 10 minutes for the Triple-Chair to a mere 5 minutes 31 seconds, so mainly halving the time. It can enhance capability on Mount Perisher by 60% and facilitate better stream of visitors across the mountain, growing raise capability within the Mount Perisher precinct by 22%.

You may also like: